Coil Slitting Machine MFS 70

Automatic Coil Cutting Machine 2 axes

Ø Maximum cut: 350mm

Length max.: 1600mm

DOUBLE PRODUVTIVITY, with carrossel system 2 axes, allowing a constant production!

Accessories

CAROUSEL SYSTEM

Coil Cutting Machine with GAINS OF UP TO 100% IN PRODUCTIVITYMetalúrgica Scain Coil Cutter works with the carousel system, which eliminates setup time, thus allowing the cutting operation to continue while a new coil is removed. Therefore, a Scain Coil Cutting Machine is an excellent choice.

SAFETY GUARANTEED BY NR12

Coil Cutting Machine offers a PRODUCTIVE PROCESS WITH TOTAL SAFETYMetalúrgica Scain's Coil Cutter has a safety system that is 100% compliant with Regulatory Standard Nº12, or just NR12. Created in 1978, it aims to ensure that machines such as the Scain Coil Cutter are safe for those who operate it and have no problems.

ADVANTAGES OF THE MFS70 COIL CUTTER

The first highlight of Metalúrgica Scain's Coil Cutting Machine is the Double Carousel System, which allows cutting the coil on one axis, while the other is outside the equipment. Therefore, it is possible to place and remove materials without having to stop work on the Coil Cutter.

Even so, the system for monitoring the production efficiency of the MFS70 Coil Cutting Machine, or in other words, the time the machine is working and also stopped, has a productivity alarm that can be configured as needed.

In the same way, the event LOG system, or, parameterizations and alarms, of Scain MFS70 Coil Cutting Machine allows access to a report with history of everything that happened and happens with the machine. Therefore, it is possible to export this data for a detailed analysis of the information contained therein.

The electronic adjustment of the width and quantity of the Coil Cutting Machine, as well as the independent control of the trimming, the creation of cut recipes through specific programs for each type of material are other advantages of the Coil Cutter.

It is also possible to point out that the Bobbin Cutting Machine allows you to assemble a mix of trimmings and up to 3 different cuts to be used in the same bobbin.

TECHNICAL CHARACTERISTICS OF COIL CUTTING MACHINE MFS70

Find out more about all the technical characteristics of Metalúrgica Scain's Ribbon Cutting Machine:

⮞ Coil Slitting Machine MFS70 with motorized main shaft and cutting disc | Electronic RPM control for both;

⮞ Movement of carriages under Linear Guides;

⮞ Drives through Servo Motors;

⮞ Main shaft coated with polyurethane bushings | Quick liner change system;

⮞ Coil Slitting Machine MFS70 with pneumatic tailstock;

⮞ Fixing the coil through an expanding bushing | Zero loss of material for fixing;

⮞ Automatic lubrication system (spraying) | With gutters and filters to return excess liquid;

⮞ Structure with epoxy painting (TOP COAT) |With fittings for easy transport;

⮞ Coil Slitting Machine MFS70 with steel carousel structure with crystal polycarbonate windows.

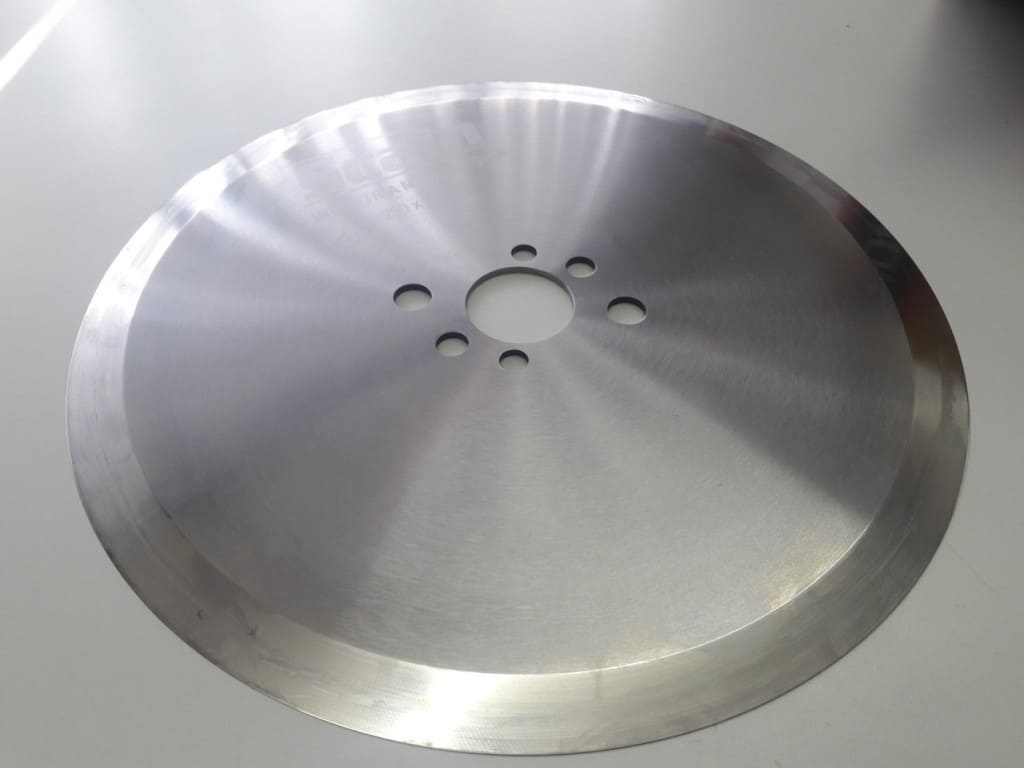

CONSUMABLES AND SPARE PARTS (SPARE PARTS) FOR COIL CUTTING MACHINE MFS70

We have all the necessary consumables to keep your MFS70 Coil Cutting Machine and your production always running safely and reliably:

⮞ Shaft lining bushings;

⮞ Cutting discs;

⮞ Cutting disc cooling fluid;

⮞ Disc sharpening service;

⮞ Special shafts with Ø smaller than 3”(76.20mm);

⮞ Self-manufactured Spare Parts.

COIL CUTTING MACHINE: MATERIALS THAT CAN BE CUT:

In addition to cutting fabric and ribbon bobbins, Scain's Bobbin Cutting Machine can cut several other materials, check the list below:

|

⮞ Asphaltic Blanket; |

⮞ Stretch Film (Up to 140mm); |

Datasheet

Request a quote

Are you interested? Do you have any doubt?

Get in touch with us or click on the button below to fill out the form and we will get back to you.

Request a quote